The Chemical and Phase Composition Analysis Laboratory (P2) performs qualitative and quantitative determination of the chemical composition of metals and their alloys. It has reference standards of alloys based on: iron, cobalt, nickel, aluminium, zinc, magnesium and copper alloys. The research is carried out in terms of both the percentage of the main alloy components and their trace amounts (ppm). In addition, the Laboratory has the ability to determine the content of gases (oxygen and nitrogen) in various grades of steel. The laboratory also has a specialized X-ray diffractometer for determining the distribution of the crystalline orientation on the surface of a single crystal - including large size single crystals elements - e.g. blades of the 1st and 2nd stage of high pressure turbine of an aircraft engine. The diffractometer is equipped with a goniometer that enables research on three-dimensional surfaces.

The basic equipment of the chemical composition analysis laboratory is:

- ARL ADVANT 'XP Sequentional XRF X-ray Sequential Spectrometer - allows analysis of up to 84 elements of the periodic table in conductive or nonconductive solids or liquids. From the monitoring of a few elements in oils, polymers, cement or quarry materials to the full analysis of glasses, metals, ores, refractories and geological materials. It provides standard-less analysis packages UniQuant® which extend the use of these instruments for simple and rapid analysis of totally unknown samples.

- ICP ULTIMA 2 HORIBA JOBIN YVON plasma emission sequencing spectrometer - qualitative and quantitative analysis of metal alloys, including specific contents of trace elements in multicomponent nickel, cobalt and iron superalloys as well as standard water and industrial wastewater analysis.

- GDS GD PROFILER HR fluorescent spectrometer - analysis of the chemical composition, type and content of elements in conductive and non-conductive materials; enabling full analysis of the chemical composition of the diffusion surface layer up to a depth of 150μm.

- ARL 3460 spark spectrometer - equipped with spectrometric lines and standards for determining the chemical composition of iron, aluminum and titanium alloys.

- LECO TCH 600 gas analyzer - Analysis of oxygen, nitrogen and hydrogen content in solid materials according to a scheme using certified calibration standards for steel, nickel superalloys, cobalt and iron, titanium alloys, aluminum and copper.

- Set of devices for sample preparation: HERZOG TP 40 400 KN mill, Dremer fume cupboard, laboratory shaker, MPW laboratory centrifuge, AND MF-50 electronic laboratory balance, sand bath, moisture analyzer, heating plate, gas burner, set of standard solutions, required laboratory glassware for sample preparation for ICP analysis.

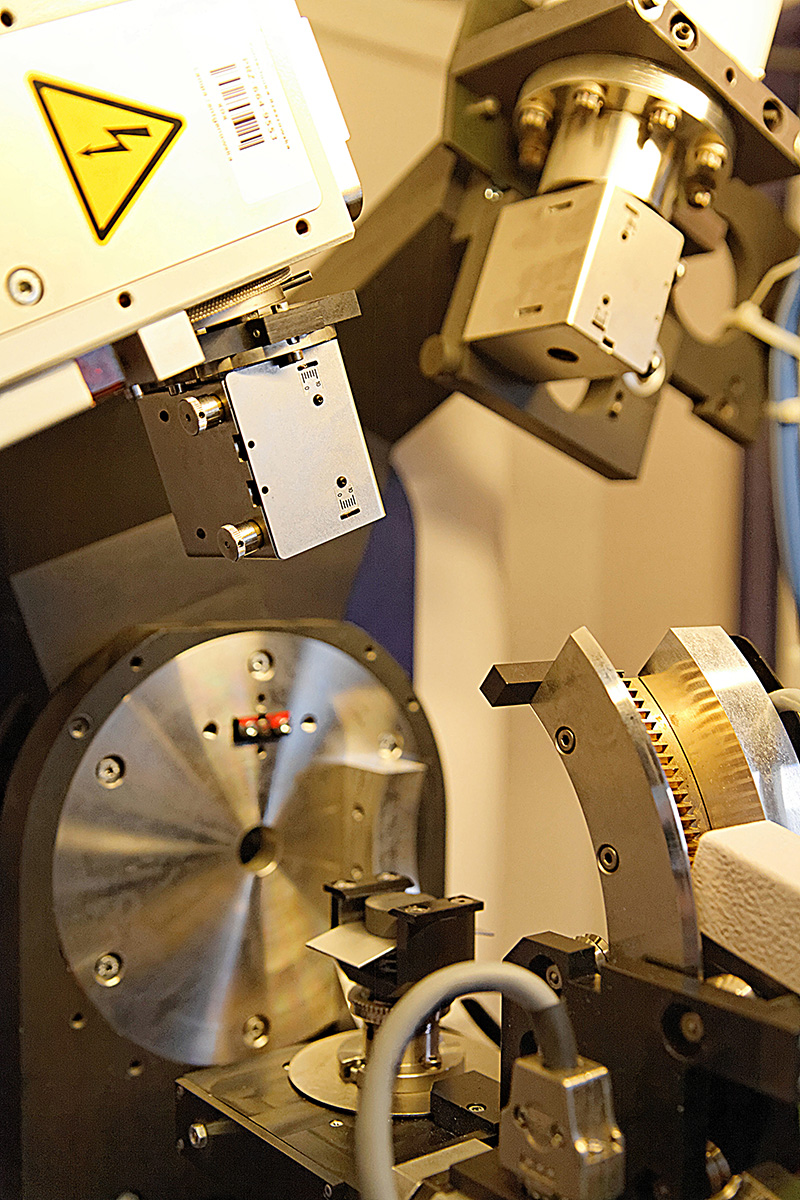

- OD-EFG 1 X-ray Diffractometer - The OD-EFG 1 diffractometer allows for the assessment of the structure perfection of single crystals of nickel superalloys using the Ω-scan method. The assessment of the structure perfection of nickel-based single crystals superalloy consists the control of the degree of compliance of withrawalaxis of the blade casting with the crystallographic direction required by the standards [001]. Hence, the angle between the single crystal draw direction and the [001] direction, denoted by α, is the fundamental parameter determining the perfection of single crystal structure. Ideally, it should coincide with the direction in which the single crystal is drawn. The OD-EFG 1 diffractometer is additionally equipped with a rotating goniometer and a movable table enabling automatic scanning of the surface of samples of complex shape. This allows you to create surface topography maps of the tested elements. The built-in laser sensor ensures a constant distance of the lamp and detector from the sample surface - each measuring point is at the same distance. The use of the OD-EFG 1 diffractometer includes a quick and ongoing assessment of the perfection of the structure of single crystals of nickel superalloys (approx. 7 seconds per measuring point).

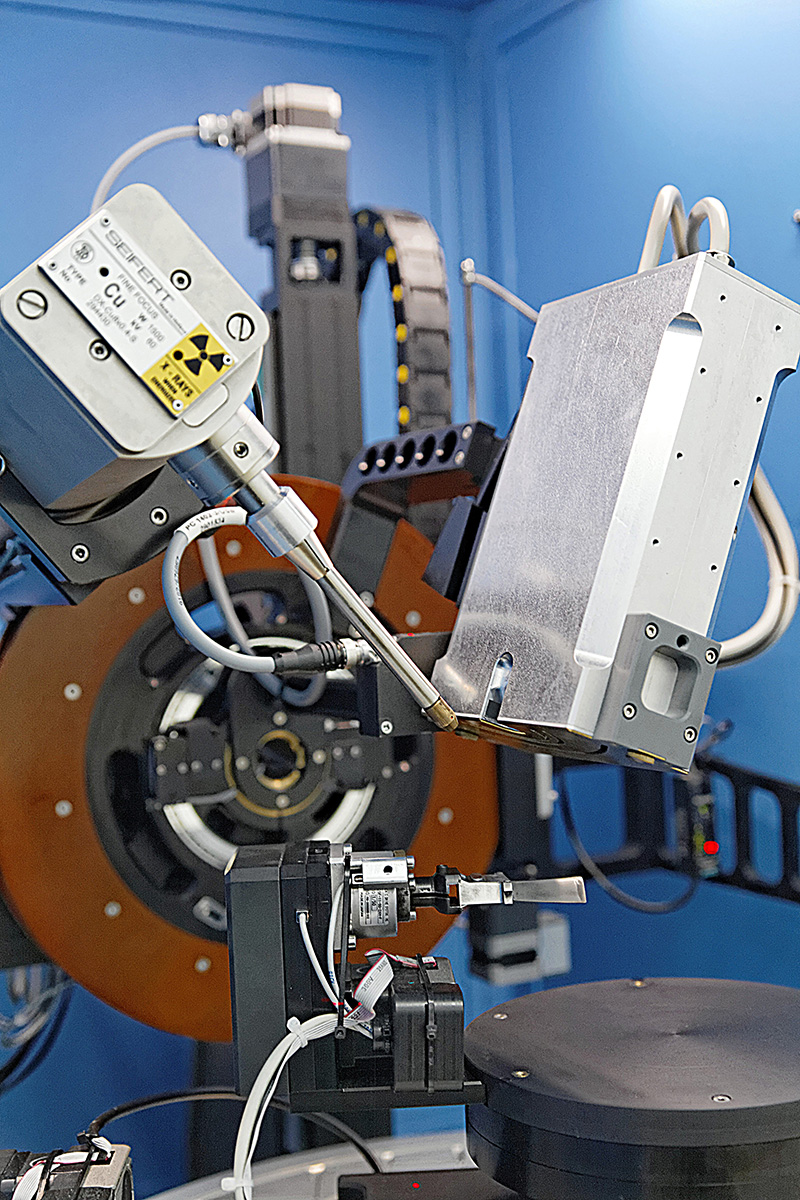

- OD-EFG 2 X-ray diffractometer - The original OD-EFG 2 X-ray diffractometer is used to assess the perfect structure of single crystals of various metals and nickel superalloys in their micro-areas - phase components; γ and γ ’crystals. In the OD-EFG 2 diffractometer, a double monochromator shaping the primary beam of radiation and a lamp with a copper anode with a power of 2600 W was used. The basic parameter determining the perfection of the crystal structure is the measurement of the value of the angle α - between the drawing direction and the [001] direction. Using the OD-EFG 2 diffractometer, it is possible to determine the full characteristics of the crystal structure perfection in the micro-regions of single crystals of nickel superalloys. Also the assessment of the perfect crystalline structure of single crystals of other metals, e.g. gold, silver, silicon or others. The OD-EFG 2 diffractometer is additionally equipped with a rotating goniometer and a movable table enabling automatic scanning of the surface of samples of complex shape. This allows the creation of maps of sample surface topography, e.g. turbine blades.

- XTRa ARL X-ray diffractometer - phase analysis (qualitative and quantitative) at room temperature and elevated temperature up to 1600°C in vacuum; determining the value of stresses in the surface layer.

- Rigaku MiniFlexII X-ray diffractometer - qualitative and quantitative analysis of the phase composition of solid materials at room temperature. The radiation source is a copper anode with a measuring range of θ = 0 - 140 ° in Bragg - Brentano θ/2θ geometry.

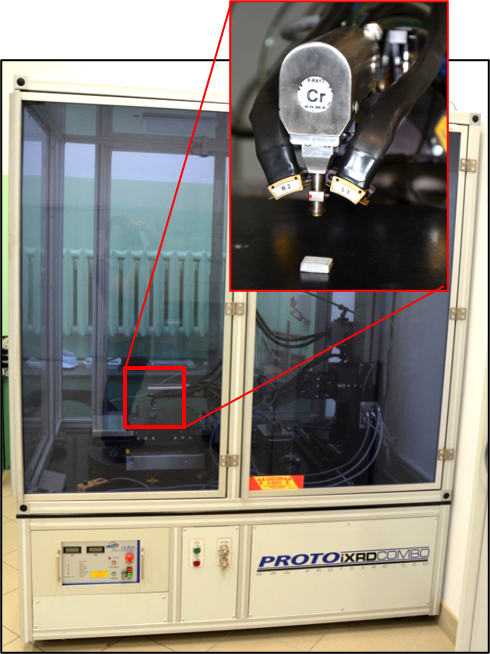

- PROTO iXRD COMBO X-ray diffractometer - analysis of the degree of plastic deformation and calculation of residual stresses in the surface layer of metal alloys. It is also possible to determine the relative volume of retained austenite. The analysis is carried out directly on an element with complex shapes without the need to prepare flat samples, used in measurements with conventional X-ray diffractometers. The value of residual stresses is calculated using the sin2Ψ X-ray diffraction method.

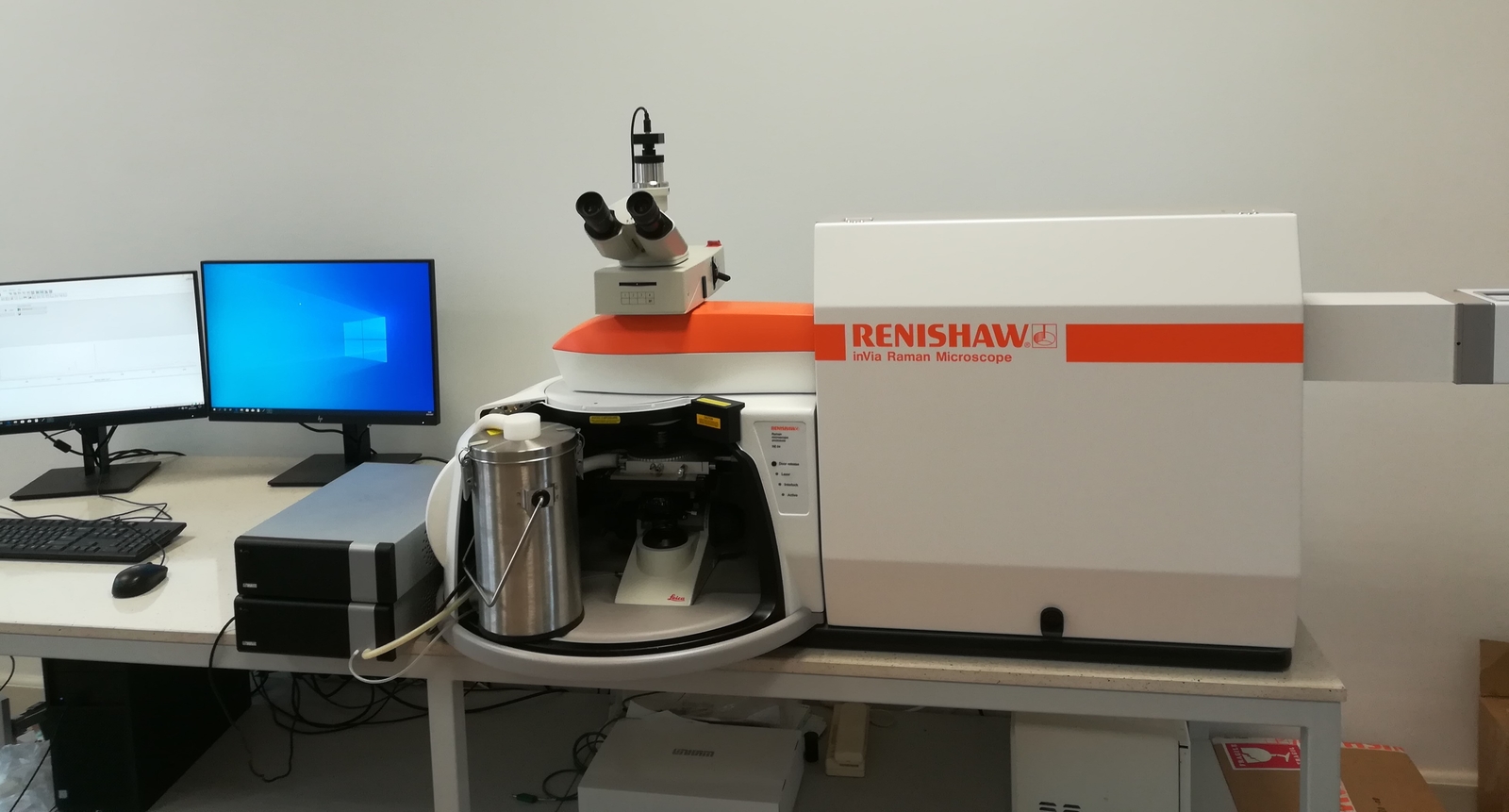

- The inVia Reflex Renishaw micro-Raman spectrometer with a Leica DM2700 microscope - The device is suitable for testing solids, liquids, solutions, suspensions and powder samples. The spectrometer is equipped with a Linkam Scientific temperature table enabling measurements in the temperature range from -190 to 600°C. Raman spectroscopy provides information about the interrelationship of atoms in a molecule, which enables the identification of chemical compounds. The temperature chamber allows for measurements as a function of temperature, both during heating and cooling of the sample with different temperature changes (from 0.1 to 150 K/min) in the range from -190 to 600°C.

Spectrometer equipment:

- Nd: YAG laser (532nm) with a total power of 50mW

- dielectric edge filter, kinematically mounted in a magnetic holder, used to cut Rayleigh lines at 532 nm, cut-off limit 100 cm-1

- diffraction grating for the VIS range: 1800 l/mm

- "Synchro Scan" system enabling continuous measurement with high resolution (0.5 cm-1 for VIS) in the full range from 100 cm-1 to 4100 cm-1

- motorized set of 4 neutral gray filters to adjust the power level of the excitation laser radiation (16 power levels, with smooth adjustment in the range: 0.00005-100%) covering the full spectral range of the spectrometer from 200 to 1050 nm

- lenses with a standard focal length with a magnification of: x20, x50, x100

- long-distance lens with a magnification of x20

- sample observation system during transmission (illuminator + condenser)